Decorate Your Bottle

How To Decorate Empty Perfume Bottles?

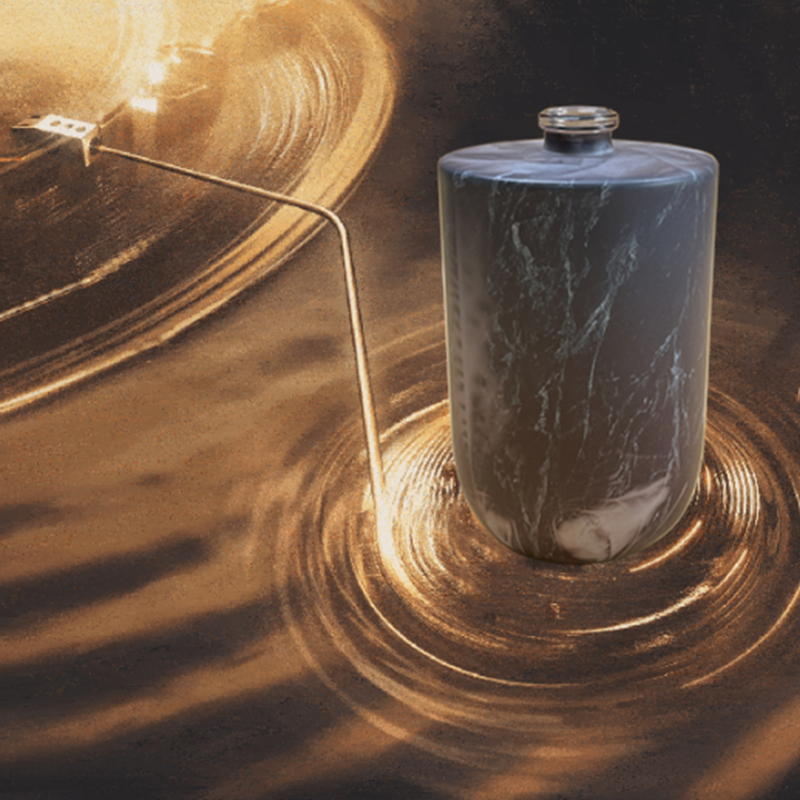

Elevate your brand with Fonli’s expert perfume bottle decoration services. From color coating to metallizing and decals, we turn plain bottles into decorative perfume bottles that stand out. Enhance your perfume bottle decor with custom finishes that add both beauty and brand value.

Color coating

• Allows for various color solutions

• Non-slip texture options available

• Gives the bottle a more vibrant look

Flocking

• Gorgeous colors

• Strong three-dimensional effect and soft touch

• Friction-resistant flat and gap-free

• Has good anti-fouling properties

Metallizing

• High gloss metallic look

• Conforms to any shape bottle

• Smooth surface

Water transfer

• High temperature resistance

• Compatible with any shape bottle or cap

• Strong adhesion and overall aesthetics

• Variety of patterns and personalized effects

Cracking

• Strong adhesion and good flexibility

• Unique pattern incomplete artistic beauty

• High hardness, good scratch resistance and water resistance

Glitter

• Shinny finishing

• Variety of colors

• Compatible with any shape bottle

Polishing

• Greatly improve the grade of glass

• Effectively removes surface blemishes

• Improve the shininess and transparency of glass

Decal

• Variety of patterns and personalized effects.

• Break through the limitations of ordinary printing

• Multiple pattern and textures can be superimposed

Frosting

• Hazy feeling increases aesthetic effect

• Make the next process stronger, like coating

• Covers up some glass surface imperfections

Lasering

• Fast and digital

• Flexible and permanent customization

• Add value with individual design options

Sandblasting

• Fine and flexible contour engraving

• Any pattern or text can be customized

• Have a embossed or debossed finishing

Want To Know More Decorations ?

FAQ About Perfume Bottle Decoration

1. Can I order cream jars in bulk?

We offer a variety of techniques to elevate your decorative perfume bottles, including color coating, flocking, metallizing, water transfer, glitter, polishing, and more. Each method is designed to enhance both aesthetics and brand identity.

2. Do you offer customization for cream jars?

Absolutely. With options like color coating and flocking, you can create a custom texture or finish—solid, transparent, gradient, or even velvet-like touch—to match your brand’s style.

3. What’s the minimum order quantity (MOQ)?

Yes. Our perfume bottle decoration processes like sandblasting, metallizing, and cracking are designed for long-lasting durability, with resistance to friction, water, and surface damage.

4. Are the jars suitable for bakhoor packaging as well?

Our decoration techniques are compatible with glass, plastic, and metal bottles in various shapes. Whether it’s an intricate design or a minimalist silhouette, we ensure a seamless finish on your decorative perfume bottles.

5. Do you provide samples before bulk orders?

Yes. Using decal, laser engraving, and water transfer printing, we bring your unique vision to life with custom logos, patterns, and textures that make your perfume bottle decor stand out on the shelf.

6. How long does production take?

For a premium look, we recommend combining techniques such as polishing for clarity, metallizing for shine, and lasering for personal touches. These finishes transform your bottles into truly luxurious decorative perfume bottles.

7. Is there a minimum order quantity for custom perfume bottle decoration?

MOQ requirements depend on the technique used. Please contact our team with your specific needs, and we’ll guide you through the most cost-effective options for your perfume bottle decor project.